When a pill leaves the factory, it doesn’t stop being monitored. In fact, the real test of its quality begins after manufacture. Stability testing is the quiet, relentless process that tracks how a drug changes over time - in heat, humidity, light, and storage. It’s not about whether the pill was made right. It’s about whether it’ll still work safely six months, two years, or five years from now.

Why Stability Testing Isn’t Optional

Imagine a cancer drug that loses potency by 15% after a year. Or an antibiotic that turns into a toxic compound when exposed to warm air. These aren’t hypotheticals. In 2021, nearly 1 in 6 drug recalls in the U.S. were tied to stability failures, according to the FDA. That’s not a manufacturing error. That’s a failure to predict how the product would behave over time. Stability testing answers one simple but critical question: Will this medicine still be safe and effective when a patient takes it? The answer isn’t guessed. It’s measured. Every batch of a new drug must be stored under controlled conditions - in chambers set to exact temperatures and humidity levels - and tested repeatedly over months and years. The data from these tests determines the expiration date printed on the bottle. No data? No expiration date. No expiration date? The drug can’t be sold.How It Works: The Science Behind the Chambers

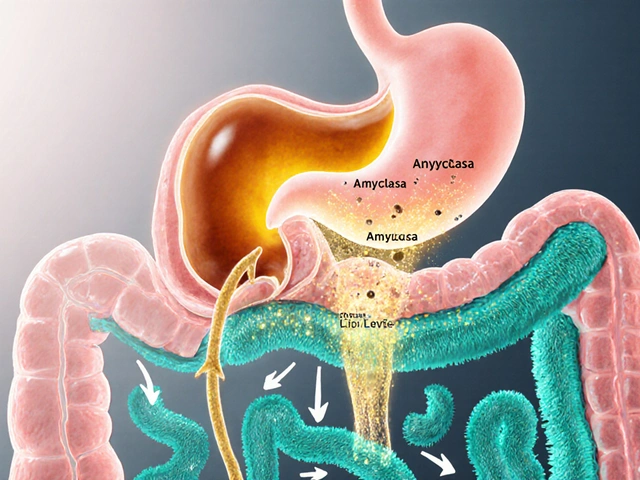

Pharmaceutical stability testing follows strict international rules set by the ICH - the International Council for Harmonisation. These aren’t suggestions. They’re legal requirements for approval in the U.S., Europe, and Japan. For most drugs, the standard long-term test runs at 25°C and 60% relative humidity - mimicking a typical home or pharmacy shelf. For hotter climates, like India or Brazil, the test runs at 30°C and 65% humidity. These aren’t random numbers. They’re based on decades of real-world data on how drugs degrade. Each product is tested at specific time points: 0, 3, 6, 9, 12, 18, 24, and often 36 months. At each point, scientists check:- Appearance: Has the tablet changed color? Does the liquid look cloudy?

- Chemical strength: Is the active ingredient still at 90-110% of the labeled amount?

- Degradation products: Are harmful byproducts forming? The FDA sets strict limits - often less than 0.1% for some toxins.

- Dissolution: Does the pill still break down properly in the body?

- Microbial growth: Is the product still sterile? Especially for injectables.

Accelerated Testing: The Fast Track That Can’t Replace the Real Thing

Companies don’t wait three years to launch a drug. So they run accelerated tests: 40°C and 75% humidity for six months. If the drug fails here, it’s a red flag. If it passes, they use statistical models - guided by ICH Q1E - to predict how it will behave over time. But here’s the catch: accelerated testing is a forecast, not a fact. A 2021 study in the Journal of Pharmaceutical Sciences showed that predictions based on accelerated data were wrong in 12% of cases. One drug looked stable at 40°C but degraded rapidly at 25°C. That’s why real-time testing is still required. Accelerated testing tells you what might happen. Real-time testing tells you what will happen.

The Hidden Cost: Time, Money, and Risk

Stability testing isn’t cheap. A single product study can cost between $50,000 and $150,000. Large companies spend $1 million or more per year. For small biotechs, that’s a huge burden - which is why 72% of them outsource to contract labs like SGS or Eurofins. It’s also slow. A new drug can’t get approved until it has at least 12 months of real-time stability data. That adds 1-2 years to development timelines. Some experts, like Dr. Robert Elder, argue this is excessive for simple, stable drugs. But regulators won’t budge. The cost of a recall - or worse, a patient harmed by degraded medicine - is far higher than the cost of testing. And it’s fragile. A single humidity spike in a stability chamber can ruin months of data. One Reddit user described a 3-month gap in their data that delayed an FDA submission by 8 months - costing $2.3 million in lost revenue. That’s why chambers are monitored 24/7, calibrated quarterly, and mapped for temperature consistency. A single faulty sensor can delay a product launch.Real Wins, Real Failures

Stability testing has saved billions. In 2022, SGS identified a chemical reaction between a new biologic drug and its glass vial - a flaw no one saw during development. Fixing it before launch prevented a $500 million failure. On the flip side, a 2021 FDA warning letter cited a manufacturer that ignored out-of-spec results for a cancer drug. They didn’t investigate why potency dropped. The drug was never approved. The delay? 14 months. Some companies are getting smarter. By using ICH Q12 guidelines, one generics manufacturer cut its stability samples by 40% without losing data quality - saving $120,000 per product annually. That’s the future: smarter, risk-based testing.

Tina Dinh

December 1, 2025 AT 06:37gerardo beaudoin

December 1, 2025 AT 14:54linda wood

December 3, 2025 AT 04:23Sara Shumaker

December 3, 2025 AT 14:37Peter Lubem Ause

December 5, 2025 AT 07:09Richard Thomas

December 7, 2025 AT 01:56Bernie Terrien

December 8, 2025 AT 04:59Andrew Keh

December 8, 2025 AT 19:32jamie sigler

December 10, 2025 AT 19:06